XPRO® 2X23TC6 Breathable Impact & Cut-Resistant Gloves – Cut level A6 Protection & Cool Mesh Venting System

Brand: XPRO®

XPRO® 2X23TC6

Brand: XPRO®

XPRO® 2X23TC6 Breathable Impact & Cut-Resistant Gloves – Cut level A6 Protection & Cool Mesh Venting System

XPRO® 2X23TC6

Premium Goatskin leather with Kevlar® lined cut Level ANSI A6, glove with ultra-flexible impact protection and CoolMesh Venting System to keep hands comfortable.

Price:

Performance ratings

EN 388:2016 3X33EP

EN 388 2016 Results: 3X33EP

Abrasion: 3

Cut (Coupe Test): X

Tear: 3

Puncture: 3

Cut (TDM-100 Test): E

Impact Protection: P

EN 388 is a European Standard. Cut Level is determined by the number of cycles it takes a spinning circular blade, that is pulled across the material under a constant weight of 500 grams, to cut the fabric. As the number of cycles increase, so does the glove’s ratings.

ABRASION 5

Abrasion Level: 5

Test Method: ASTM D3389-10

The ISEA 105-2016 standard outlines test methods for abrasion and is scored from 0-6. The ASTM D3389-10 is used for uncoated gloves, and the end point (failure) is the number of abrasion cycles when the first thread or yarn is broken. The larger numbers of cycles indicate greater abrasion resistance of the product and a higher Abrasion Level.

CUT A6

Cut Level: A6

New edition ISEA 105-2016 outlines a new test method for determining cut scores and a revised scale from A1-A9.

PUNCTURE 3

Puncture Level: 3

The ISEA 105-2016 blunt force puncture testing uses a probe to simulate a tear or burst hazard. The test measures the amount of force needed for a blunt probe to pierce through PPE material. Results are given in Newtons, which is converted into a 1-5 scale and spans from 10 newtons (Level 1) to 150+ newtons (Level 5) of puncture resistance.

IMPACT 2

Impact Level: 2

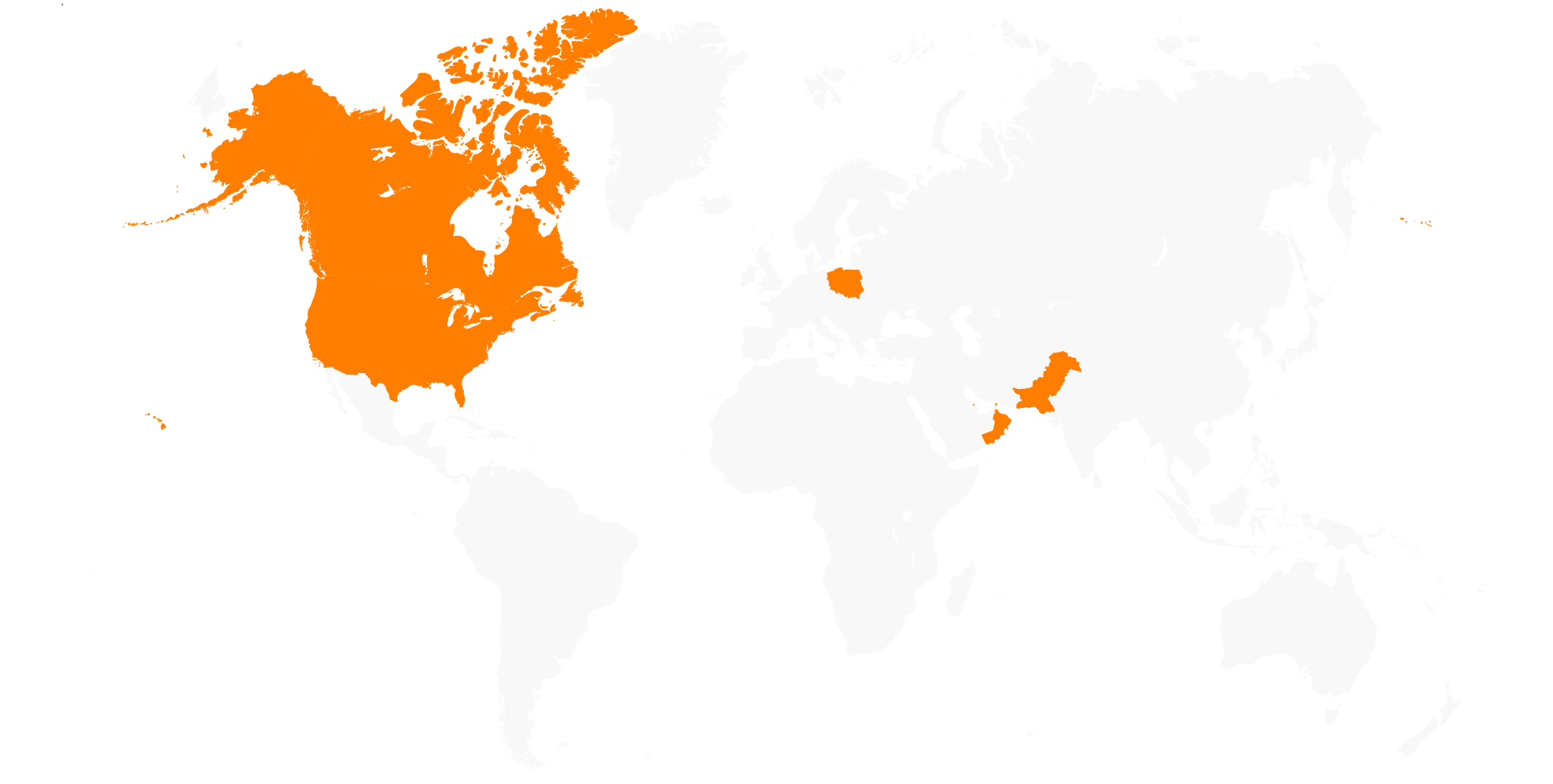

ISEA 138 is a new, voluntary standard for the North American market designed to accurately classify different levels of impact protection offered by the impact-resistant gloves on the market.

EN ISO 21420:2020

The EN ISO 21420:2020 standard outlines the general requirements and test methods for protective gloves. It covers aspects such as design, construction, comfort, efficiency, and safety, ensuring gloves meet necessary performance criteria. This standard applies to all protective gloves, including those used in industrial environments, and replaces the previous EN 420:2003 standard.

European conformity

The CE mark (Conformité Européenne) indicates that a safety product meets the essential health, safety, and environmental protection requirements of the European Economic Area (EEA). It ensures that the product complies with relevant EU directives and can be sold freely within the EEA, providing assurance of its safety and quality.

Category II

Category II (Cat II) gloves are designed for intermediate risks, meaning they provide protection against mechanical, thermal, or chemical hazards but are not intended for extreme dangers. These gloves must be tested and type-approved by an EU-recognized institute and labeled with pictograms indicating their protective functions.

EN 388:2016 3X33EP

EN 388 2016 Results: 3X33EP

Abrasion: 3

Cut (Coupe Test): X

Tear: 3

Puncture: 3

Cut (TDM-100 Test): E

Impact Protection: P

EN 388 is a European Standard. Cut Level is determined by the number of cycles it takes a spinning circular blade, that is pulled across the material under a constant weight of 500 grams, to cut the fabric. As the number of cycles increase, so does the glove’s ratings.

ABRASION 5

Abrasion Level: 5

Test Method: ASTM D3389-10

The ISEA 105-2016 standard outlines test methods for abrasion and is scored from 0-6. The ASTM D3389-10 is used for uncoated gloves, and the end point (failure) is the number of abrasion cycles when the first thread or yarn is broken. The larger numbers of cycles indicate greater abrasion resistance of the product and a higher Abrasion Level.

CUT A6

Cut Level: A6

New edition ISEA 105-2016 outlines a new test method for determining cut scores and a revised scale from A1-A9.

PUNCTURE 3

Puncture Level: 3

The ISEA 105-2016 blunt force puncture testing uses a probe to simulate a tear or burst hazard. The test measures the amount of force needed for a blunt probe to pierce through PPE material. Results are given in Newtons, which is converted into a 1-5 scale and spans from 10 newtons (Level 1) to 150+ newtons (Level 5) of puncture resistance.

IMPACT 2

Impact Level: 2

ISEA 138 is a new, voluntary standard for the North American market designed to accurately classify different levels of impact protection offered by the impact-resistant gloves on the market.

EN ISO 21420:2020

The EN ISO 21420:2020 standard outlines the general requirements and test methods for protective gloves. It covers aspects such as design, construction, comfort, efficiency, and safety, ensuring gloves meet necessary performance criteria. This standard applies to all protective gloves, including those used in industrial environments, and replaces the previous EN 420:2003 standard.

European conformity

The CE mark (Conformité Européenne) indicates that a safety product meets the essential health, safety, and environmental protection requirements of the European Economic Area (EEA). It ensures that the product complies with relevant EU directives and can be sold freely within the EEA, providing assurance of its safety and quality.

Category II

Category II (Cat II) gloves are designed for intermediate risks, meaning they provide protection against mechanical, thermal, or chemical hazards but are not intended for extreme dangers. These gloves must be tested and type-approved by an EU-recognized institute and labeled with pictograms indicating their protective functions.

- Premium Goatskin Leather Palm: Provides dexterity and outstanding abrasion resistance.

- Cool Mesh Venting System: Enhances airflow by up to 60% for superior heat dissipation.

- A6 Cut Protection: Engineered yarn lining ensures safety against sharp objects.

- Ultra-Flexible Impact Protection: Shields hands while maintaining dexterity.

- Perfect Shape & Sizing: Designed for ergonomic fit and comfort.

- Available in Winter Version (2X23TTC6): Provides insulation for cold environments.

- Available in Higher Cut Levels (A3 to A9): Customizable protection for specialized applications.

Application: Appliance Manufacturing, Oilfield Operations, Mining & Excavation, Automotive Industry, Construction Work, Glass Handling, Machining & Metal Handling, Metal Stamping & Paper Production

Trade: Industrial Safety Gloves, Cut-Resistant Work Gloves, High-Dexterity Utility Gloves, Heavy-Duty Impact Gloves

Hazard Protection: Cut Resistance (A6), Impact Resistance, Abrasion Protection, Heat Dissipation & Breathability, Grip Enhancement (Wet & Dry), Industrial Safety Compliance